Tungsten is one of the toughest and most durable metals known to man. Not only that, but it’s extraordinarily dense with a high melting point and great heat-distributing capacity, making it invaluable for industrial purposes. With its ability to endure extremely high-pressure conditions, tungsten has become an essential element in many industries, from engineering to aerospace applications. But what exactly are the unique properties of tungsten metal and how can they benefit your business? In this blog post, we’ll explore these topics in depth so you can gain a better understanding of why tungsten metal is an immensely versatile material for industrial use.

The Physical and Chemical Characteristics of Tungsten

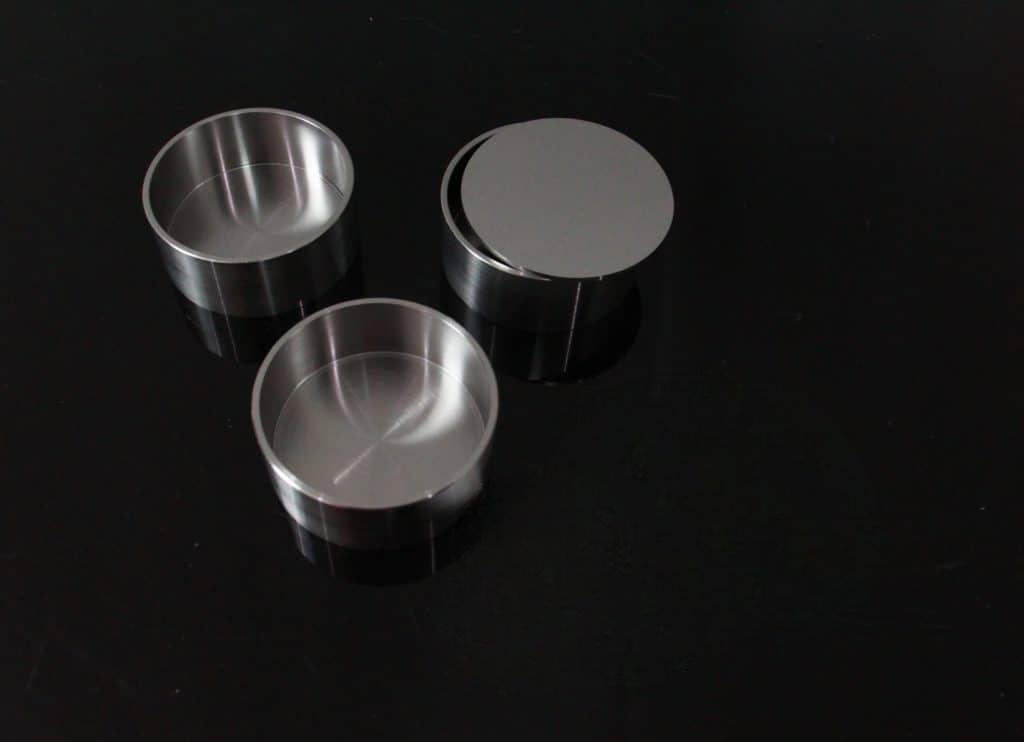

Tungsten, known for its high melting point and hardness, has unique physical and chemical characteristics that make it a popular choice in various applications. In its pure form, tungsten is a silver-gray metal that is resistant to corrosion and has a high density. It is also ductile and malleable, allowing it to be easily shaped into wires or sheets. On the chemical side, tungsten does not react with non-oxidizing acids but can dissolve in aqua regia or potassium hydroxide solutions. Its ability to absorb radiation and retain its strength at high temperatures makes it valuable for use in nuclear power plants. With such impressive properties, it’s no surprise that tungsten finds its way into everything from incandescent light bulbs to heavy-duty cutting tools used in the aerospace industry.

Why Tungsten is a Preferred Material in Harsh Conditions

When it comes to tough environments, tungsten is the material of choice for many applications. This rare metal boasts the highest melting point of any element, making it incredibly resilient in extreme heat. Additionally, it has excellent corrosion resistance and is extremely dense, making it perfect for sturdy and durable products. These properties make it ideal for use in harsh conditions, such as aerospace and defense applications, where reliability and performance are critical. From high-temperature furnaces to mining drills, tungsten’s unique characteristics have made it the go-to choice for manufacturers who need materials that can withstand demanding environments.

Comparing Tungsten with Other Metals in Durability and Strength

Tungsten, also known as wolfram, is widely recognized as one of the toughest metals on the planet. Its exceptional strength and durability make it a popular choice in a variety of applications, from industrial tools to jewelry. But how does it compare to other metals in terms of these properties? Well, it turns out that tungsten is stronger and denser than most other metals, and has a higher melting point than all but a few. This means that it is less likely to deform or become damaged under pressure or heat, making it ideal for use in high-stress environments. Compared to more commonly used metals like steel and titanium, tungsten definitely holds its own in terms of toughness and resilience.

With its extreme toughness and resistance to temperatures, tungsten has solidified its status as a preferred scripting material for craftsmen and engineers alike. Its refusal to succumb to wear and tear means that its applications in vital industries, such as aerospace and nuclear power plants, are rightfully growing. The incredible survival rate of the metal under pressure comes off as a crucial factor in why it is used in certain manufacturing processes. We can observe that when compared to other metals, tungsten’s uncompromising spirit easily pushes it above the competition. For anyone looking for a sturdy building material with unmatched qualities- then tungsten is their go-to option! If you are looking for ways you can make use of this durable metal, then why not start by visiting your local store or website? You may be surprised at just how many possibilities the innovative metal offers!