TZM Alloy is a molybdenum alloy (0.4-0.54% Ti, 0.06-0.12 %Zr, 0.01-0.04% C, balance Mo), which is consolidated by either the P/M or vacuum arc-casting processes. It is of great utility due to its high strength and high-temperature applications, especially above 2000 °F. This alloy can also be named as molybdenum alloy TZM, molybdenum TZM, molybdenum high-temperature TZM, titanium-zirconium-molybdenum alloy.

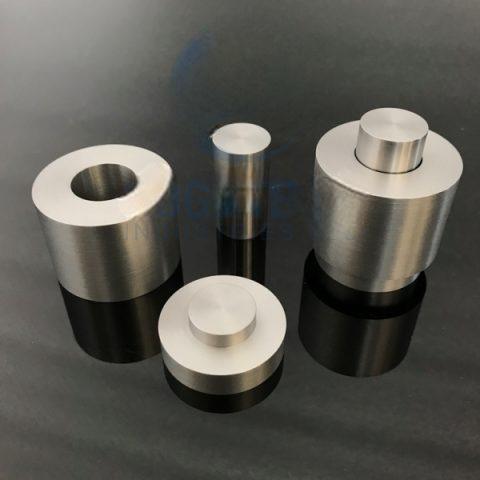

Alloy Parts

TZM Molybdenum has a higher recrystallization temperature, higher strength, and hardness at room and elevated temperatures than pure Molybdenum. It offers twice the strength of pure moly at temperatures over 1300 °C. The recrystallization temperature of TZM Alloy is approximately 250 °C higher than pure molybdenum and it offers better weldability. For high-strength applications such as rocket nozzles, furnace structural components, and forging dies, it can be well worth the cost differential.

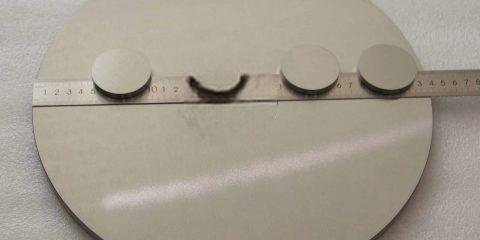

We produce a wide range of molybdenum and molybdenum alloy mill products using the powder metallurgy (PM) method. The availability of products from this process gives users many options in selecting a material to satisfy their specific application requirements.

TZM Molybdenum mill products available from either process include forging billets, bars, rods, sheets, plates, and foil. All forms in basically the same size range as pure molybdenum except thin foil. Visit semi-finished to check the size range for each pure molybdenum product.

Molybdenum TZM can be processed by all common metalworking processes, and no special equipment or procedures are required to produce parts with precise dimensions and excellent finish. TZM can process simple parts, very complex parts, shapes and very small complex parts.

TZM Parts

Specification for Alloy Wire

| Item Name | TZM Alloy Wire |

| Specification | ASTM B387, TYPE 364 |

| Size | 0.5mm-4.0mm diameter x L |

| Shape | Straight wire, rolled wire |

| Surface | Black oxide, chemically cleaned |

Alloy Rods

Specification for Mo Alloy Rod

| Item Name | TZM Alloy Rod |

| Specification | ASTM B387, TYPE 364 |

| Size | 4.0mm-100mm diameter x <2000mm L |

| Process | Drawing, swaging |

| Surface | Black oxide, chemically cleaned, Grinding |

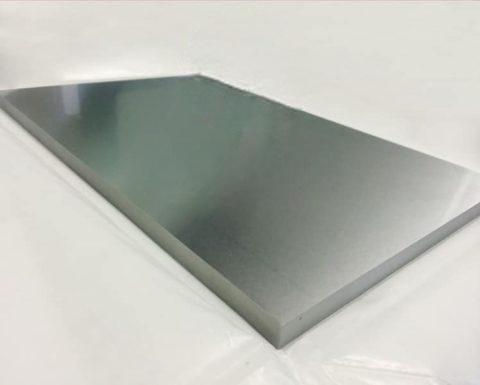

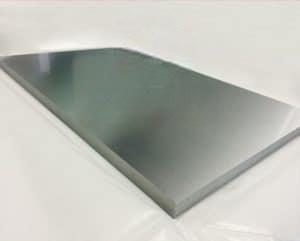

Alloy Plate

Specification for Mo Alloy Plate

| Item Name | TZM Alloy Plate |

| Specification | ASTM B386, TYPE 364 |

| Size | 4.75mm-50mm thickness x W x L |

| Process | Forging, rolling |

| Surface | Chemically cleaned, Grinding |

Alloy Tube

Specification for Mo Alloy Tube

| Item Name | TZM Alloy Tube |

| Specification | ASTM B387, TYPE 364 |

| Size | 0.8”-20” OD, 106” max length for a single piece of tube |

| Process | Sintering, gun drilling |

| Surface | Black oxide, chemically cleaned, Grinding |

We can also provide Mo alloy parts according to customers’ drawings.

MOLYBDENUM TZM Alloy QUICK FACTS

- High Melting Point at 2623°C

- More than 10 Times the Creep Resistance than Pure Mo

- Higher Recrystallization Temperature than Pure Mo

- Higher Strength and Hardness than Pure Mo

- Operating Temperatures of 1000°C to 1400°C

Application Areas

-For high-temperature components in the aerospace industry, such as nozzle shrouds, combustion chambers, and heat exchangers.

-For components in nuclear applications that require high-temperature resistance and strength, such as control rod drives and fuel cladding.

-For furnace components such as heating elements and insulation brackets, due to their high-temperature resistance and strength.

-For medical devices such as dental implants and surgical instruments, due to their biocompatibility and high strength.

These are just a few of the many applications for TZM alloys. As this high-performance material continues to gain popularity, new applications may emerge in the future.

Packaging for molybdenum alloy products

The standard package for molybdenum alloy products is a wooden crate so that the products can be protected during handling and transportation. A carton package for small pieces is also used.

Please send your request to inquiry.crucible@winnewtech.com, and we will reply you within 3 minutes

inquiry.crucible@winnewtech.com

Non-Ferrous Crucible Inc.

Tel: +86-755-84112759

Fax: +86-755-84112759

No. 7, Gongye 2nd Road, Jinsha, Kengzi, Pingshan, Shenzhen, China.

518122

inquiry.crucible@winnewtech.com