Shape Memory Effect: “Shape Memory” describes the restoration of the original shape of a plastically deformed sample upon heating.

Superelastic Effect: An elastic (reversible) response to an applied temperature, caused by a phase transformation between the austenitic and martensitic phases of a crystal.

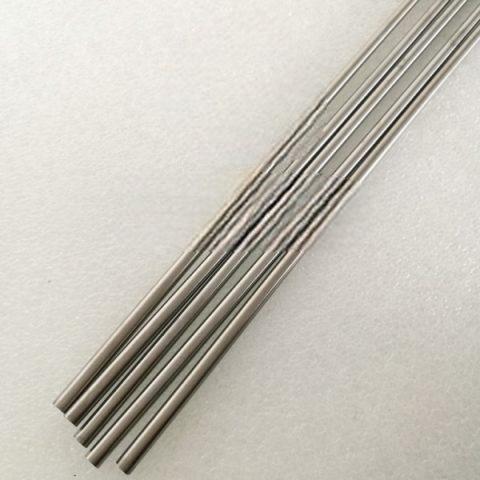

Nitinol is a metal alloy, that exhibits two closely related and unique properties: shape memory and superelasticity. We provide both types of NiTi rods.

Nitinol Cylinder

Keywords: Superelastic alloy rod, shape memory alloy rod, nickel-titanium alloy rod, shape memory alloy, Ti-Ni alloy rod

Non-Ferrous Crucible Inc. manufactures nitinol rods from various grades of nickel-titanium alloy commonly used in medical applications as well as for other various applications. Medical grade nitinol material comprises nickel and titanium in nearly equal atomic weight percentages; per ASTM F2063, nickel content of 54.5-57 wt% is specified for use in surgical implants. Nitinol with different compositions and phase transformation temperatures can be used for other applications.

Specification of our nickel-titanium alloy rod

| Product Name | Nitinol Rod |

|---|---|

| Specification | ASTM F2063-12 |

| Af Temperature | -10°C to 120°C |

| Size | >0.2” Diameter |

| Surface | Black, Pickled, Polished |

| Other type | Rod, bar, rectangular bar, and other customized shape |

Nitinol threaded rods, cylinders, and rings can be machined from rods. We provide Niti threaded rods with custom Af points and sizes, even the high-temperature nitinol with high hardness.

Threaded rod

Nitinol Threaded Rod Specification

| Product Name | Nitinol Threaded Rod |

|---|---|

| Specification | ASTM F2063-12 |

| Af Temperature | -10°C to 120°C |

| Size | >0.2” Diameter |

| Surface | Black, Pickled, Polished |

| Threads | >M3, or ANSI SPEC. |

Available products: Nitinol threaded rods, bolts, fasteners, nuts, washers, nickel-titanium alloy fasteners.

There are two main types of NiTi alloys: superelastic and shape memory, which are determined by their transition temperatures. Superelastic NiTi alloys have lower temperatures, while shape memory NiTi alloys have higher temperatures. To help you choose the best NiTi alloy for your application, Non-Ferrous has divided the superelastic and shape memory categories into grades with more stringent temperature ranges.

Nitinol Rods

Superelastic NiTi alloys are often used in medical devices. Superelastic grades have transition temperatures between -20°C and 22°C [-4°F and 71.6°F]. Shape memory NiTi alloys are often used in actuators and other industrial applications. Shape memory grades have transition temperatures between 22°C and 80°C [71.6°F and 176°F], with some grades having transition temperatures above 85°C [185°F].

Packing information for our nitinol

Our nitinol is mostly packed in wooden crates, which can protect the nitinol products during transportation and handling.

We can also program custom shapes when heating nitinol rods, please send us your request to inquiry.crucible@winnewtech.com for any needs on titanium nickel alloy.

Please send your request to inquiry.crucible@winnewtech.com, and we will reply you within 3 minutes

inquiry.crucible@winnewtech.com

Non-Ferrous Crucible Inc.

Tel: +86-755-84112759

Fax: +86-755-84112759

No. 7, Gongye 2nd Road, Jinsha, Kengzi, Pingshan, Shenzhen, China.

518122

inquiry.crucible@winnewtech.com