Molybdenum rods, TZM Alloy, and MoLa Alloy rods can be manufactured into wire, electrode, steel-making additives, electric vacuum parts, gas pipes, lead wire, poles, sidebars, daily-use glass, optical glass, insulation material, and glass fiber. Small crucibles and tubes are machined from Moly rods.

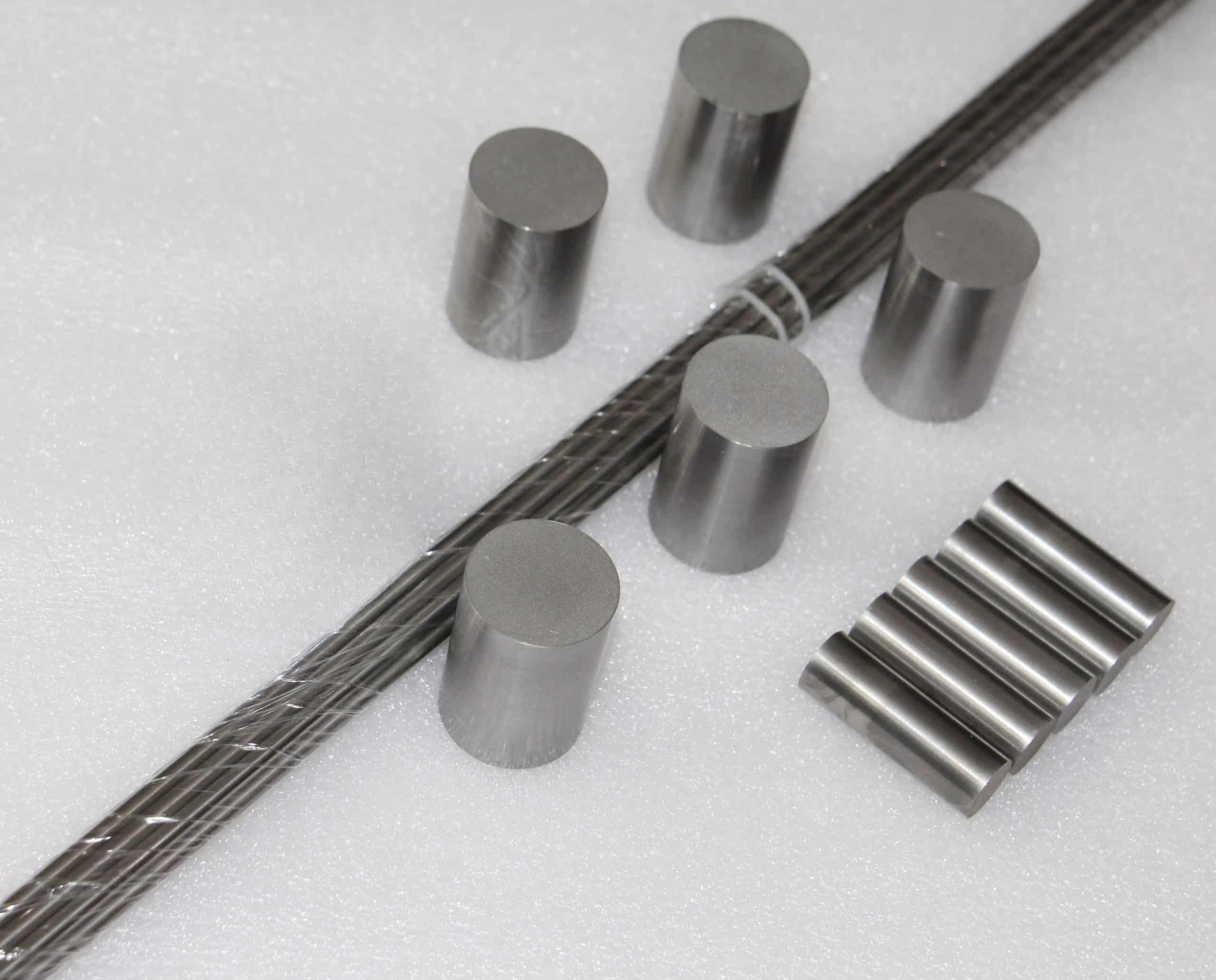

Moly rods packing

About Material

Molybdenum is used for its extremely high melting point and relative flexibility. Molybdenum has a melting point of 2,623 °C. Molybdenum has a high elastic modulus, and only tungsten and tantalum have higher melting points. Typical applications for Molybdenum are crucibles, evaporation boats, propulsion components, x-ray tubes, the lighting industry, glass melting electrodes, high-temperature furnaces, sputtering targets, heat sinks, heating elements, electrodes, stirrers, orifice plates, support members, mandrels, shields, sintering trays, filaments, furnace windings, thermocouple sheaths, nose cones, nozzles, jet tabs, contacts, brazing fixtures, boring bars, tools, heat radiation shields, cathodes, and aircraft and missile parts and nuclear energy applications where high-temperature resistance is crucial.

Specification for molybdenum rod:

| Product | Molybdenum Rod |

|---|---|

| Standard | ASTM B387, Type 361/364 |

| Process | Drawing, swaging |

| Purity | Mo≥99.95% |

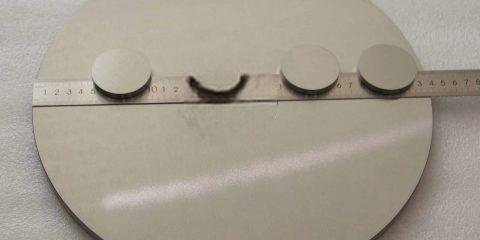

| Size | 0.16”~6.0” diameter x L |

| Surface | Grinding, Finish turning |

Moly rod is manufactured as random length pieces or cut to customized lengths in diameters ranging from 0.16 inches to 6.00 inches.

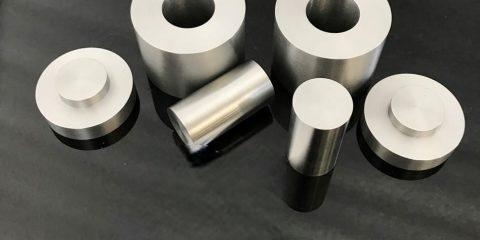

Moly Cylinder / Rod

Molybdenum materials have high hardness and strength, the tubes cannot be made by the same rolling process as titanium tubes. The raw material of small outer diameter tubes is rods. Therefore, molybdenum and molybdenum alloy tubes are obtained by gun-drilling molybdenum rods, TZM alloy rods, and molybdenum-lanthanum (MoLa) alloy rods.

Surface Finish for Mo rods

Black –Surface covered with processing lubricants and oxides.

Cleaned – The surface is chemically cleaned to remove all lubricants and oxides.

Ground – The surface is centerless ground to remove all coating and to achieve precise diameter control.

Other sizes of Mo rods and parts machined from rods can be manufactured per drawings, we also provide TZM alloy rods and Mo-La alloy rods per drawings. Send your inquiry to inquiry.crucible@winnewtech.com.

Packing of Moly rod

Regularly, our molybdenum rods (TZM alloy rod, MoLa alloy rod) are packed in wooden crates, cartons are also used for small rods and cylinders.

Please send your request to inquiry.crucible@winnewtech.com, and we will reply you within 3 minutes

inquiry.crucible@winnewtech.com

Non-Ferrous Crucible Inc.

Tel: +86-755-84112759

Fax: +86-755-84112759

No. 7, Gongye 2nd Road, Jinsha, Kengzi, Pingshan, Shenzhen, China.

518122

inquiry.crucible@winnewtech.com