Molybdenum and Tungsten are both refractory metals and are ideally suited to make furnace parts used at high temperatures. With their special properties, they are the perfect choice for components in the furnace construction industry. Molybdenum and tungsten furnace parts are mostly used for high-temperature furnace sapphire growth furnaces and other high-temperature furnaces.

Mo boat

Properties for molybdenum & tungsten furnace parts:

-High operating temperatures

-Outstanding creep resistance

-High level of dimensional stability

-Extremely pure

-Excellent corrosion resistance

-Low coefficient of expansion

Products & process for Molybdenum furnace parts:

-Crucible: Sintered directly or machined from rod & ingot

–Container: Sintered directly or machined from rod & ingot

–Self: Machined, welded from rods & sheets

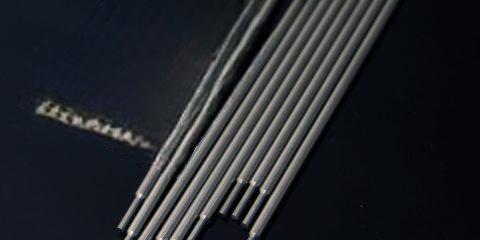

–Heating element: machined from rods, wire, strip

–Heat shields: welded and machined from sheets

–Boats: Stamped or welded from sheets

Mo container

Specification of Moly furnace parts

Material: ASTM B386/387, Type 361

Purity: Mo, 99.95%

Application temperature environment: < 1900°C

Dimensions: Per drawings

High-quality molybdenum products provide exceptional heat resistance. The price of molybdenum furnace parts depends on size, complexity, configuration, and additional requirements specified in the order. We also provide tungsten furnace parts.

Please send us your drawings of the molybdenum heater to inquiry.crucible@winnewtech.com.

Please send your request to inquiry.crucible@winnewtech.com, and we will reply you within 3 minutes

inquiry.crucible@winnewtech.com

Non-Ferrous Crucible Inc.

Tel: +86-755-84112759

Fax: +86-755-84112759

No. 7, Gongye 2nd Road, Jinsha, Kengzi, Pingshan, Shenzhen, China.

518122

inquiry.crucible@winnewtech.com