Non-Ferrous Crucible Inc. provides tantalum tubes including seamless tubes and welded tubes & pipes. Welded Ta tubing & piping are made from strips and foil, welded tubes can be with the wall thickness is thin and large OD.

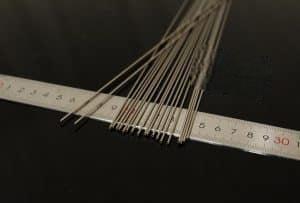

Tantalum tubes

Other shaped and machined parts of tantalum are also available upon request.

Tantalum tube and tantalum tungsten alloy tube

Material: R05200, R05400, R05252(Ta-2.5W)

Size: Diameter: φ1.0-150mm, Thickness: 0.2-5.0mm, Length: 100mm-12000mm

Standard: As per ASTM B521

Tantalum tubing with <5mm OD can also be named as tantalum capillary, this is only available for pure tantalum. We can provide Ta capillary with small heights, that will be marker bands.

- Seamless Tantalum Tube

Seamless pipe shall be manufactured by any seamless method capable of producing a product that meets the requirements of this specification. For those looking for tantalum pipe with thicker walls, we recommend seamless tantalum pipe.

- Welded tantalum tubes

Welded pipes shall be made from flat-rolled products using automatic or semi-automatic fusion welding processes without adding filler metal.

For those who are looking for a thinner wall tantalum pipe, we recommend a welded tantalum pipe. Welded pipes are made of tantalum plates. Their surface quality is good because they are polished after welding.

Tantalum Tungsten Alloy Tubes

Tantalum and Tantalum Alloy Material Grades

R05200, unalloyed tantalum, electron-beam furnace or vacuum-arc melt, or both

R05400, unalloyed tantalum, powder-metallurgy consolidation.

R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace or vacuum-arc melt, or both.

R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

We guarantee a purity of 99.95% for our sintered quality tantalum (metallic purity without Nb) with both melted tantalum (R05200) & sintered tantalum (R05400).

Our sintered tantalum is used for those tricky situations: due to our powder metallurgy production process, sintered tantalum is particularly fine-grained. As a result, the material is very easy to work with and excels due to its excellent surface quality and robust mechanical properties.

Melted tantalum is usually more economical to produce than sintered tantalum and provides sufficient quality for many applications. However, the material is neither as fine nor as homogeneous as R05400 tantalum. They both work excellently in different fields.

Pure sintered quality tantalum and pure melted quality tantalum share the following properties:

-High melting point of 2996 °C

-Good cold ductility

-Recrystallization between 800 °C and 1200 °C (depending on the level of deformation and purity)

-Outstanding resistance against aqueous solutions and metal melts

-Superconductivity

-High level of biocompatibility

Packing information for our Tantalum

Our tantalum is mostly packed in wooden crates, which can protect the products during transportation and handling.

We can also provide custom tantalum pipe, tubing, tantalum capillary, and marker bands, please send us your request to inquiry.crucible@winnewtech.com for any needs on tantalum rolling products.

Please send your request to inquiry.crucible@winnewtech.com, and we will reply you within 3 minutes

inquiry.crucible@winnewtech.com

Non-Ferrous Crucible Inc.

Tel: +86-755-84112759

Fax: +86-755-84112759

No. 7, Gongye 2nd Road, Jinsha, Kengzi, Pingshan, Shenzhen, China.

518122

inquiry.crucible@winnewtech.com