Refractory materials are those substances with high temperature and pressure resistance. Some of the most common types are bricks, which are rectangular in shape. They are available in standard and special dimensions. They are also used for nuclear power plants and other applications requiring high temperatures. The properties of refractory materials vary according to the purpose of their use. In general, the refractory materials are made of inorganic nonmetal materials with refractory degrees of up to 15800C.

Refractory bricks come in standardized sizes and shapes. The shapes are used to estimate the number of bricks needed for an installation. For instance, clay bricks are aluminum silicate refractory materials made of corundum, mullite, glass, and cristobalite. Refractory bricks are an important part of the smelting process, and are manufactured in the shapes of arches, tubes, and circular apertures.

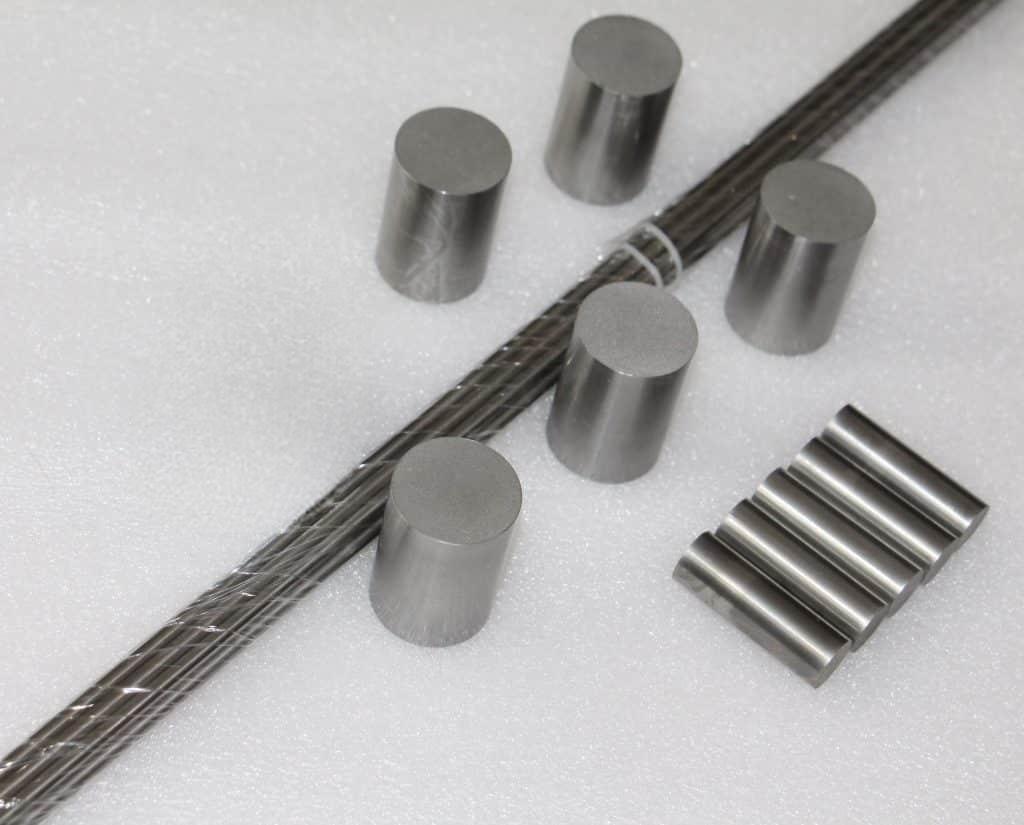

Refractory metals can be made of a variety of materials. Some refractory metals are useful for tools and casting molds that require high temperatures. Other refractory metals are used for chemical reactions in corrosive environments. Their high melting points and high resistance to creep deformation make them ideal for these applications. If you’re interested in learning more about refractory metals, watch the following video.

Another important consideration when choosing refractory metals is the melting point. Refractory metals are a great material to work with in a wide variety of environments, and can be molded to fit various shapes. For example, in a metal kiln, refractory steel is a good choice for a high-temperature furnace. Because it is so durable, it won’t corrode, and can be easily cleaned.

Refractory materials are used in industrial processes for a variety of purposes. From the manufacturing of a petrochemical to the use of heat sinks, refractory products are essential for the vast majority of industrial processes. They are used directly in the manufacturing of most products, and many of them are recycled. They can also be reused or recycled. In addition to their direct and indirect uses, refractory products are crucial for numerous other industries.

Several types of refractory materials are used in chemical and industrial processes. The most common type is magnesium-chrome refractories, which are made primarily of magnesium oxide. The magnesium-chrome alloy has a high refractoriness and is a good choice for corrosive environments. Its melting point of 2030 degC makes it a good choice for heating elements in a nuclear power plant.

Refractory bricks are made of clay, alumina, silica, and kaolin. Alumina is a good insulator and has reflective properties. However, it is also a poor conductor of heat. The refractory bricks used in nuclear power plants are often very expensive and are used to build buildings. Most of them have a gray or yellowish color and are sold as building bricks.

Refractory materials are made of a variety of different materials. The basic composition of refractory metals and alloys is unique and makes them a great choice for reactors. This material is also used in tools, lubricants, and nuclear reactor control rods. The chemical properties of refractory metals make it a good choice for a range of applications, including metallurgy.

The chemical properties of refractory materials are important in industrial processes. They can be highly reactive with acidic substances. For example, silica bricks are used in the iron and steel industries. They are inexpensive and can withstand high temperature. Aside from being cheap, silica bricks can last for years when properly treated. The lifespan of refractory bricks depends on their use. In a glass melting furnace, the coatings can last up to 10 years.

Refractory bricks and kilns are used in industrial processes. Because of their high melting points, they have an advantage over other types of bricks and tiles. They can withstand very high temperatures, and yet not lose their structure or thermal conductivity. Some refractory bricks even exhibit a color that makes them easy to distinguish from other materials. This makes them a great choice for ceramics.

Refractory bricks are a popular choice for lining boilers. They are durable and heat-resistant and are an excellent choice for liners and flue linings. These bricks are also used in soaking pits, as well as reactor chambers. They can be used for secondary insulation and are very durable. They can be insulated in various ways, such as in the form of ladles. For instance, they can be made of ceramic fibres.