Electrochemical devices will play a key role as one of the solutions for the transition to renewable energy. Technologies such as water electrolyzers, fuel cells, and redox flow batteries can help achieve widespread electrification while coping with intermittent energy production. Both the cost and performance of these energy solutions have improved dramatically over the past decade.

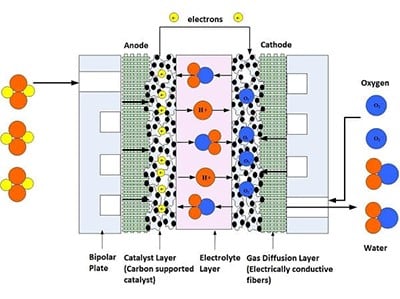

At the heart of these devices is the so-called stack where the electrochemical reactions take place. Key components include the membrane/diaphragm, electrocatalyst, porous transport layer (PTL), and bipolar plates.

The porous transport layer, sometimes called gas diffusion layer (GDL) or current collector, has a variety of functions that affect the performance and durability of the electrochemical device. An ideal porous transport layer should:

Enable efficient flow of gaseous/liquid reactants/products

Have high electrical and thermal conductivity

Have corrosion resistance to specific environments

Have a regulated interface with other components such as the membrane and electrocatalyst

Porous transport layer (PTL) is an important component of polymer electrolyte membrane water electrolyzer (PEMWE) and is responsible for better utilization of catalyst layer (CL). PTL can transport reactant water to anode and cathode CL, remove generated oxygen and provide good conductivity for efficient electron conduction.

Non-Ferrous Crucible Inc. provide sintered metal powder metal and sintered metal fiber media which can be modified depending on customer request.